Why is it a good idea to have one

of our personal scan tools, even for a new

vehicle? Read this story from our repair journals about a vehicle just out

of warranty, and you'll find out why ...

As in many cases, this 98 Dodge Ram pickup arrived under tow to our shop

with an urgent request for

us to find out what happened. The customer had described the sudden occurrence

of a loud knocking sound, at which point he had shut the engine down and

called for a tow truck. I pulled the pan off and discovered that the rod

bearings had failed, with most of the trouble originating from number 6

cylinder.

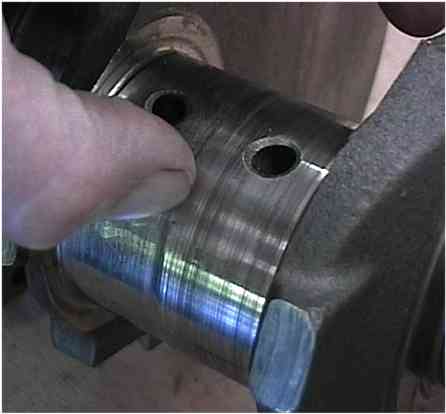

As you can see in the picture on the right, the bearing shells had worn

through to the point where they were disintegrating, causing unrecoverable

damage to the crank. All the other rod bearings were worn down and would

have failed soon.

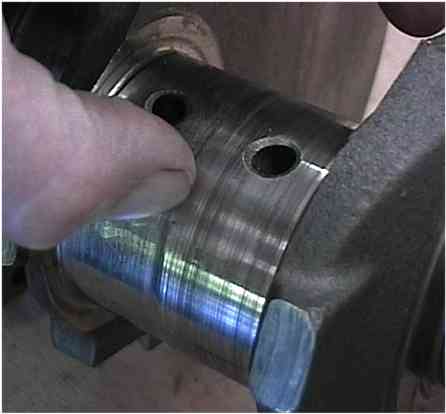

Those bearing shells are from the number 6 rod connection. There are two pairs of

bearings arrange side by side on the crank journal. One half had deteriorated

before the other, leaving a 50 thou ridge gouged out of the crank journal,

probably the cause of the loud knocking sound. The ridge can be clearly

seen in the picture below, in the area around my thumbnail. This was the

worst case, but I could see that all the bearings were substantially worn.

As I pulled it apart further,  it

became apparent that this engine would require a new crank and more or

less a complete rebuild to bring it back to normal functionality. Since it

had just passed out of warranty (75,000 miles), I prepared a repair

estimate and discussed it with my client; he then gave us the 'go ahead'

to start the rebuild process.

it

became apparent that this engine would require a new crank and more or

less a complete rebuild to bring it back to normal functionality. Since it

had just passed out of warranty (75,000 miles), I prepared a repair

estimate and discussed it with my client; he then gave us the 'go ahead'

to start the rebuild process.

Despite receiving a new set of faulty hydraulic lifters (internal pistons

jamming, which would have blown the engine again immediately had I not

spotted the problem), I managed to get the engine removed, rebuilt and

reinstalled in less time than the factory spec of 40 hours. I then drove

the vehicle for several days to ensure that proper break-in procedure was

exercised and just to make sure everything felt like it was running

correctly. This driving period also allows the OBD computer system to

're-learn' the operational parameters so that the client gets it back in

optimized running condition.

This was also no thanks to the 'cab forward' recessed engine design which

puts the back half of the motor well into the firewall pocket. So where do

they put the distributor? In the front? On the side of the block? No, they

put it right at the back of the engine, deep in the darkest recesses of

the firewall pocket, with very little clearance for adjusting anything!

I'm not a contortionist, but I had to become one for a half a day

...

Technician's Note:

When attaching the CPS (Crank Position Sensor) at the rear of the

engine, be sure to get the stamped spacer from your Chrysler parts dealer

to set the proximity spacing relative to the internal pulse generator.

This is not mentioned in the service manual and it won't run beyond a

rough idle without it.

So why did all this happen? I can only speculate about this, as we may

never know the true cause. I looked for obvious causes, such as blocked

oil passages, oil pump failure, customer abuse, etc. but none of these

things were evident.  In

talking with the client, I learned that it had previously cracked a head

between the valve ports on the port bridge on one cylinder due to arcing between the

secondary coil wire and one of the plug high tension wires, caused by poor routing

separation (Chrysler has issued a TSB - Technical Service

Bulletin about this known problem).

In

talking with the client, I learned that it had previously cracked a head

between the valve ports on the port bridge on one cylinder due to arcing between the

secondary coil wire and one of the plug high tension wires, caused by poor routing

separation (Chrysler has issued a TSB - Technical Service

Bulletin about this known problem).

Thus I knew it had been previously stressed and probably overheated, which

may have contributed to the bearing failure. After talking further to my

client about some of the history of this vehicle, I learnt that while my client was away traveling, he had experienced

misfiring problems and gone into the nearest Chrysler dealer for

servicing. They were apparently very busy and not able to look at his

vehicle for five days, so he went to an independent shop where they

replaced the cap and rotor with aftermarket parts.

When I examined the

ignition cap and rotor, I found definite evidence of timing problems.

Looking at the

rotor, I found that the rivet that holds the rotor electrode in place had

become loose, allowing it to flop about with a considerable amount of

motion inside the distributor as it was running. Aside from a lot of wear, the distributor

cap had plenty of white powdery material near the contact points, a sure

sign of arcing and ozone generation. Furthermore, the carbon rotor pickup

'button' in the center of the cap was also heavily worn.

All of this adds up to the possibility of a condition known as

pre-ignition,  whereby

the spark plug fires prematurely as the piston is still coming up to TDC

(Top Dead Center). This causes a great deal of stress on the connecting

rod bearings and piston assembly as the plug is not supposed to fire until

the piston has more or less reached to top of its travel, ready to go back

down again. Essentially, it was attempting to reverse the direction of the

piston in mid-travel, creating exceptional loads on the piston assembly

(including bearings). Since this engine doesn't have a knock sensor, the

client may not have been aware of this condition.

whereby

the spark plug fires prematurely as the piston is still coming up to TDC

(Top Dead Center). This causes a great deal of stress on the connecting

rod bearings and piston assembly as the plug is not supposed to fire until

the piston has more or less reached to top of its travel, ready to go back

down again. Essentially, it was attempting to reverse the direction of the

piston in mid-travel, creating exceptional loads on the piston assembly

(including bearings). Since this engine doesn't have a knock sensor, the

client may not have been aware of this condition.

Yes, hindsight is a great thing, but our scan tool could have prevented this failure, as it would have shown

clearly that there were timing issues associated with this engine. This

would have been especially important in this case, as the engine does not

have a knock sensor and thus would not necessarily generate an OBD trouble

code, causing the 'check engine light' to come on.  To

get an idea of the kind of detailed reporting available on your PC with

our scan tool, please see the actual sample data screens from our Toyota

Solara demo vehicle below. A relatively small investment today

can potentially save you thousands of dollars in repair bills down the

line, as was the case here. And please, don't forget we have our

online clinic facility where we are standing by

online to help you understand any problems you may be having ...

To

get an idea of the kind of detailed reporting available on your PC with

our scan tool, please see the actual sample data screens from our Toyota

Solara demo vehicle below. A relatively small investment today

can potentially save you thousands of dollars in repair bills down the

line, as was the case here. And please, don't forget we have our

online clinic facility where we are standing by

online to help you understand any problems you may be having ...

Thanks, Henry

it

became apparent that this engine would require a new crank and more or

less a complete rebuild to bring it back to normal functionality. Since it

had just passed out of warranty (75,000 miles), I prepared a repair

estimate and discussed it with my client; he then gave us the 'go ahead'

to start the rebuild process.

it

became apparent that this engine would require a new crank and more or

less a complete rebuild to bring it back to normal functionality. Since it

had just passed out of warranty (75,000 miles), I prepared a repair

estimate and discussed it with my client; he then gave us the 'go ahead'

to start the rebuild process.  In

talking with the client, I learned that it had previously cracked a head

between the valve ports on the port bridge on one cylinder due to arcing between the

secondary coil wire and one of the plug high tension wires, caused by poor routing

separation (Chrysler has issued a TSB - Technical Service

Bulletin about this known problem).

In

talking with the client, I learned that it had previously cracked a head

between the valve ports on the port bridge on one cylinder due to arcing between the

secondary coil wire and one of the plug high tension wires, caused by poor routing

separation (Chrysler has issued a TSB - Technical Service

Bulletin about this known problem). whereby

the spark plug fires prematurely as the piston is still coming up to TDC

(Top Dead Center). This causes a great deal of stress on the connecting

rod bearings and piston assembly as the plug is not supposed to fire until

the piston has more or less reached to top of its travel, ready to go back

down again. Essentially, it was attempting to reverse the direction of the

piston in mid-travel, creating exceptional loads on the piston assembly

(including bearings). Since this engine doesn't have a knock sensor, the

client may not have been aware of this condition.

whereby

the spark plug fires prematurely as the piston is still coming up to TDC

(Top Dead Center). This causes a great deal of stress on the connecting

rod bearings and piston assembly as the plug is not supposed to fire until

the piston has more or less reached to top of its travel, ready to go back

down again. Essentially, it was attempting to reverse the direction of the

piston in mid-travel, creating exceptional loads on the piston assembly

(including bearings). Since this engine doesn't have a knock sensor, the

client may not have been aware of this condition.  To

get an idea of the kind of detailed reporting available on your PC with

our scan tool, please see the actual sample data screens from our

To

get an idea of the kind of detailed reporting available on your PC with

our scan tool, please see the actual sample data screens from our